How to Make Paper

with Plant Fiber and Recycled Paper

Making paper from plant fiber is hard labor-but it is fascinating too-and the color of the sheets when dry always surprises.

The process begins with fiber pieces about 1-2 inches long. I like to start with fiber that's been outside all winter and well dried, or rhetted. I run these through my chipper-vac two or three times and it does a great job of chopping into the perfect size. The process begins with fiber pieces about 1-2 inches long. I like to start with fiber that's been outside all winter and well dried, or rhetted. I run these through my chipper-vac two or three times and it does a great job of chopping into the perfect size.

Next

comes the cooking! I like to do this outside over a campfire. I'll get two or

three big pots of fiber in the soda ash (some use lye) solution brewing over

a crackling fire, sometimes overnight. The fiber needs to cook until the fibers

can be pulled apart with the thumb test. (One of those technical paper-making

terms :-) Next

comes the cooking! I like to do this outside over a campfire. I'll get two or

three big pots of fiber in the soda ash (some use lye) solution brewing over

a crackling fire, sometimes overnight. The fiber needs to cook until the fibers

can be pulled apart with the thumb test. (One of those technical paper-making

terms :-)

Once the fiber passes the thumb test, it is rinsed, and rinsed, and rinsed, until the water runs clear. Now it is blended or beaten - depending on the fiber - to loosen up and hydrate those fibers even more. I use a line-up of bar blenders, and/or stainless steel mallets when necessary. Once the fiber passes the thumb test, it is rinsed, and rinsed, and rinsed, until the water runs clear. Now it is blended or beaten - depending on the fiber - to loosen up and hydrate those fibers even more. I use a line-up of bar blenders, and/or stainless steel mallets when necessary.

At this point in the process, not only are your arms tired, but you have a gooey clump of fiber in your blender, or on your beating board, that looks nothing at all like paper pulp! But that's great - what it should look like now is a rather non-descript damp mass of, well, it's not necessarily pretty at this point. But the best is just around the corner - pulling the sheets! At this point in the process, not only are your arms tired, but you have a gooey clump of fiber in your blender, or on your beating board, that looks nothing at all like paper pulp! But that's great - what it should look like now is a rather non-descript damp mass of, well, it's not necessarily pretty at this point. But the best is just around the corner - pulling the sheets!

This is started by filling your vat with the desired amount of water and add handfulls of the hydrated fiber. There is no set formula here, just what feels right to you. The vat is stirred until the pulp appears-like a thundercloud rolling over the plains-and mixes into the water. If inclusions are to be in the sheets, you add them now as you pull. This is started by filling your vat with the desired amount of water and add handfulls of the hydrated fiber. There is no set formula here, just what feels right to you. The vat is stirred until the pulp appears-like a thundercloud rolling over the plains-and mixes into the water. If inclusions are to be in the sheets, you add them now as you pull.

Sheet formation is accomplished with a mold and deckle - two rectangular frames, one with a screen, and held together one atop the other. In one continuous motion, the pair are dipped perpendicularly into the vat, then turned horizontally and pulled up toward you in one motion. The excess pulp is slooshed over the sides as the screen is rocked back and forth, forwards and backwards, with increasing gentleness. Sheet formation is accomplished with a mold and deckle - two rectangular frames, one with a screen, and held together one atop the other. In one continuous motion, the pair are dipped perpendicularly into the vat, then turned horizontally and pulled up toward you in one motion. The excess pulp is slooshed over the sides as the screen is rocked back and forth, forwards and backwards, with increasing gentleness.

Once the right amount of pulp is floating evenly across the screen, it is held still until it stops dripping. Then the deckle is removed and the newly formed sheet is couched onto the felt, ready to be pressed. Once the right amount of pulp is floating evenly across the screen, it is held still until it stops dripping. Then the deckle is removed and the newly formed sheet is couched onto the felt, ready to be pressed.

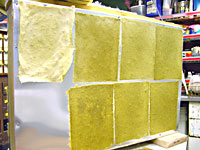

I have a 12 ton hydraulic press built into a frame which works quite well for pressing posts up to 50 felts thick. The post is left to drip a while, then placed on this hot-box dryer for a smooth finish on one side (hot-press) or placed on newsprint and cardboard in a drying box with a fan for 24 hours(cold-press) till dry.

Making paper from recycled office paper is very similar, and a tiny bit less labor intensive. It is run through a paper shredder, soaked in water to soften, then rinsed several times. It only takes the blenders seconds to render it into a fluffy, cloudy pulp that is a pleasure to pull. Making paper from recycled office paper is very similar, and a tiny bit less labor intensive. It is run through a paper shredder, soaked in water to soften, then rinsed several times. It only takes the blenders seconds to render it into a fluffy, cloudy pulp that is a pleasure to pull.

Both the plant fiber pulp and the recycled paper pulp can be dyed along the way, or combined, anything your imagination can come up with! Pretty soon, you're walking around looking at just about everything around you and wondering... how would that look in paper?

Thank you so much for taking the time to find out how to make handmade paper from plant fiber and recycled paper. Please browse the site, you might find something you like. If you have any questions e-mail us at paper@mlcltd.com

Martha J.

Grand Junction, CO

Eron K.

Blachly, OR |